Post

Let's take a look at some of the perks that come with metal stamping and CNC processing in and of themselves:Stamping metal is a process that can be utilized in many different fields and possesses the attributes of high productivity, rapid speed, and a broad range of potential applications. When stamping metal, the kind of tools that have to be used are determined by the final product that is being made. For example, the production of metal components for automobiles requires a unique set of tools compared to the production of metal components for medical devices. Additionally, the production of hard tools has a lower overall cost compared to the production of soft tools.

Let's take a look at some of the perks that come with metal stamping and CNC processing in and of themselves:Stamping metal is a process that can be utilized in many different fields and possesses the attributes of high productivity, rapid speed, and a broad range of potential applications. When stamping metal, the kind of tools that have to be used are determined by the final product that is being made. For example, the production of metal components for automobiles requires a unique set of tools compared to the production of metal components for medical devices. Additionally, the production of hard tools has a lower overall cost compared to the production of soft tools.

The majority of our common casing types include things like motor casings, micro motor casings, instrumentation casings, mobile phone casings, and so on. These different casing types need to be distinguished from one another based on the materials that they are made out of. The materials can be broken down into three primary categories, which are alloy casings, plastic casings, and composite material casings. Alloy casings are online milling service the most common type. The term "alloy casings" encompasses a wide range of different types of casings, including the tensile alloy casing made of stainless steel that was discussed in this article.

Stainless steel is a material that is frequently used for the casings of a wide variety of products. This is due to the fact that stainless steel can effectively prevent corrosion, in addition to having high levels of strength and resistance to wear. The primary component of stainless steel is a material that possesses the qualities of lightness and beauty, both of which contribute to the material's excellent utility. These qualities are chromium, which is also the element that gives stainless steel its name. In addition, the price of stainless steel casings is not an unreasonable amount of money. When compared to casings made of plastic, those made of stainless steel are significantly more wear-resistant and long-lasting than their plastic counterparts. The majority of casings are made of plastic, but the stainless steel casing is not only more aesthetically pleasing but also more functional than the majority of plastic casings; this is one of the reasons why people prefer it.

When contrasted with other alloy materials, the stainless steel shell possesses superior corrosion resistance and more efficient heat dissipation. These advantages allow it to outperform other alloy materials. These advantages are not available when working with alloy materials. When compared to the casing made of other materials, the one made of stainless steel offers superiority in terms of comprehensive performance at a lower cost. This satisfies the requirements of society as a whole at this point in time, which is why it is so widely used. Not only does it have a sturdy aluminum alloy metal texture, but it also has an easy processing, high flexibility, low weight, high corrosion resistance, shock resistance, and sound insulation. These are just some of its other desirable characteristics. Because of these characteristics, it not only possesses a strong aluminum alloy metal texture, but it is also able to significantly increase the added value of products that are made with aluminum alloy shells. This is because of the fact that it can increase the strength of the aluminum alloy metal texture. In addition, as a result of the exceptional benefits that the shell made of aluminum alloy possesses, it is widely utilized in a variety of industries, such as the power electronics industry, the instrumentation industry, and others.

The processing of the aluminum profile shell is done based on the aluminum profile that was obtained by stretching aluminum. This profile serves as order cnc machined parts the basis for the processing. has a high level of convenience, which has resulted in the expansion of its potential fields of application. In the majority of cases, there are slots for circuit boards located within. , has a high level of convenience.

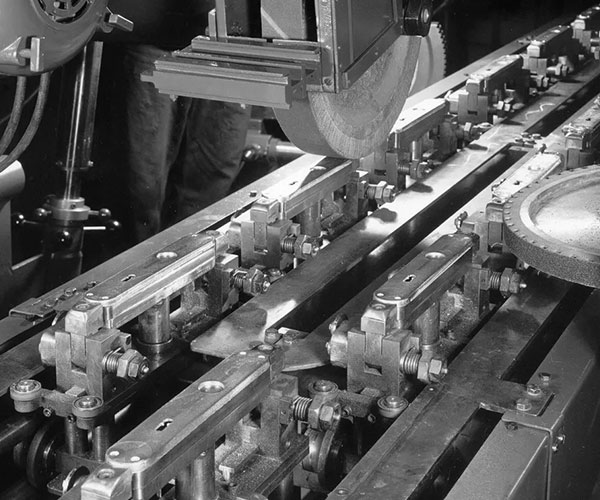

Computer Numerical Control, also known as CNC, is an acronym that describes a device that serves multiple purposes and describes the manner in which a machine tool is controlled to produce the desired shape in such a way that each tool carries out its designated function and produces accurate results. CNC is a device that serves multiple purposes and describes the manner in which a machine tool is controlled to produce the desired shape. CNC machines make use of a wide variety of tools in order to complete the primary responsibilities for which they were designed. The components that make up CNC processing technology can be broken down primarily into two categories: new processing technology and traditional processing technology. While metal stamping is most commonly used in the automotive industry, CNC machining is essential in the medical and aerospace industries. This is because metal stamping requires a lower level of precision than CNC machining does, but both processes are able to produce the same number of parts. The reason for this is that CNC machining requires a higher level of precision. In addition to this, these systems incorporate quality control checks to guarantee that the rate of production is kept constant.

In the production line for CNC machining, there milling parts online is a significant amount of leeway for variation. It is possible to apply a wide variety of processes to a component or finished product. Additionally, the production process calls for the utilization of a wide variety of mechanical equipment and fixtures. On the other hand, the module level of automation technology is the most important level of automation technology. This level includes things like flexible manufacturing that makes use of CNC lathes. In most cases, the method of closely combining in-house production with outsourced processing will be utilized for product parts. For instance, the electroplating process, sandblasting, air oxidation, silk screen printing ink laser marking, and any number of other one-of-a-kind procedures will be allowed to be outsourced to third-party manufacturers. The workshop typically needs to immediately complete a large number of warehousing forms and will typically observe a manufacturing form that is in the shape of a line because there are so many essential components.

komentarze